Discover an effortless flooring solution with DecoFloor®, the revolutionary new timber-look aluminium floorboards by DECO Australia. The following installation guide outlines a range of installation techniques. If you require further assistance, please contact us.

WARNING:

Care and Personal Protective Equipment (PPE) should be worn at all times when handling DecoFloor® products. Failure to do so risks potential serious injury, disablement or death. Simultaneously, ensure workspace is clean and free from dust, sawdust, metal fines and/or shavings. Processing of floorboard in areas with excessive dust, sawdust, metal dines and/or shavings risks potential damage to the finished surface.

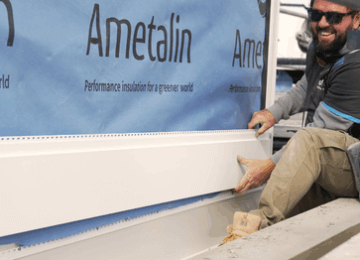

Installation Surface

When installing DecoFloor®, care should be taken to adequately prepare the installation surface, to ensure it is fit for its intended purpose. Before installing the boards, the surface should be levelled to remove any depressions in the floor. DecoFloor® is intended to be installed on a subfloor that is solid, hard, flat, clean, dry and structurally stable, such as a concrete base or wood substrates, and preparations including layinghigh quality underlay should be undertaken prior to installation.

Fixing Details

When fixing DecoFloor® products, it is recommended that the boards are screw fixed at a maximum of 1200mm centres, when applied to a solid floor base, and roughly 20-50mm before the end of each board.

Staggering the Boards

While installing DecoFloor® Boards, you must stagger the end joint. This will provide strength and structural stability throughout the floor. It is the best to keep the end joint pattern as random as possible.

Important Information

All DecoFloor® boards are supplied in 6.5m lengths. As part of the manufacturing process, the first 10mm of both ends of the extrusion are taped and not imaged, therefore each floorboard will need to be trimmed by 15mm on each end to remove the tape and provide a clean finish. After the removal of each end, the useable length is 6.45m.

Floorboards

DFJ - 70mm DecoFloor Joiner

The DecoFloor® Joiner will prevent deflection on the end joint between the floorboards due to live load occurrence.Rectangular Hollow Section

For use as Skirting, RHS can be supplied in various sizes and colour matched to the finish you require.Carpet Connector (Available upon request)

For use in transitioning between flooring and carpet. It contains three parts, Base, Joiner, and Ramp. DECO can colour match the ramp to your desired finish.DF03 - Starter Strip

The Starter Strip is the base profile that helps level the first board to begin the installation, while providing a seamless finish.Angle

For use as Skirting and Transitioning between areas. The Angles can be supplied in various sizes and colour matched to the finish you require.All testing has been done using the detail provided in this installation guide and in order to claim the performances set out here within, the detail in this guide must be followed.

AS1530.1

Methods for fire tests on building materials, components and structures – Combustibility test for materials.

AS 1530.3

Methods for fire tests on building materials, components and structures – Simultaneous determination of ignitability, flame propagation, heat release and smoke release.

AS 3837-G1

Method of test for heat and smoke release rates for materials and products using an oxygen consumption calorimeter. DecoFloor has been tested to and complies with this standard.

AS 4586:P4

Slip Test. DecoFloor achieves a Slip Resistant Value (SRV) of P2.

AS 3715

Performance testing for thermoset powder coatings applied to aluminium intended for exterior architectural applications.

ClipFix Concrete Screws 5x32mm

Galvanised or stainless steel.

Supplied by Installer or DECO.

Sealant/ Adhesive

Deco recommends the use of high-quality sealant and adhesives.

Supplied Installer

Impact Driver

A high-quality Impact Driver with an appropriate driver bit is recommended for fixing all extrusions to the building structure.

Mitre Saw

A high-quality Mitre Saw equipped with an aluminium cutting blade is recommended for cutting the boards to length and trimming the boardends.

Table Saw

A high-quality Table Saw is recommended for ripping the final (top) board to the correct dimension for finishing of the installation.

Underlayment

High quality underlayment is strongly recommended for installation. This provides stability, noise reduction and supports the locking system.

Supplied by Installer