WARNING:

Care and Personal Protective Equipment (PPE) should be worn at all times when handling DecoClad® products. Failure to do so risks potential serious injury, disablement or death. Simultaneously, ensure workspace is clean and free from dust, sawdust, metal fines and/or shavings. Processing of cladding boards in areas with excessive dust, sawdust, metal dines and/or shavings risks potential damage to the finished surface.

Preparation:

To ensure a straight, consistent and parallel installation, it is strongly recommended that a level is used to position each cladding board throughout the installation.

Supporting Structure and Fixing:

All framing should be constructed from steel or timber according to the requirements of the NCC and relevant standards to ensure resistance to wind loads, with studs positioned at maximum 600mm centres. For Non-Cyclonic vertical applications ensure that the wall is battened out or has studs at 600 centres; in Cyclonic applications studs should be installed at 450 centres. When using a Joining Connector for “Classic Installations”, or a Flushline Tee section for “Flushline Installations”, ensure that a stud, batten or noggin is installed behind the connector.

Fixing Application Requirements

When fixing DecoClad® to the wall, fixings should be used every 450mm for cyclonic applications or every 600mm for non-cyclonic applications. 30mm x 10G Self Tapping Panhead or Button Head screws (galvanised or stainless steel) shall be used in all circumstances.

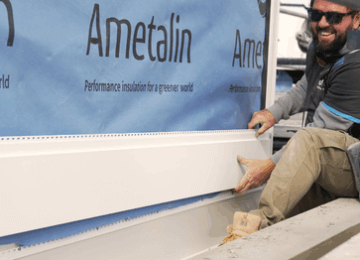

Sarking/Building Wrap

To ensure a waterproof application, a sarking or building wrap layer should be installed first to prevent any water penetrating the building. Care should be taken to ensure that all penetrations are carefully sealed to ensure water does not penetrate the building wrap or sarking.

Important Information

All DecoClad® and accessories are supplied in 6.5m lengths. As part of the manufacturing process, the first 10mm of both ends of the extrusion are taped and not imaged, therefore each cladding board will need to be trimmed by 15mm on each end to remove the tape and provide a clean finish. After the removal of each end, the useable length is 6.45m.